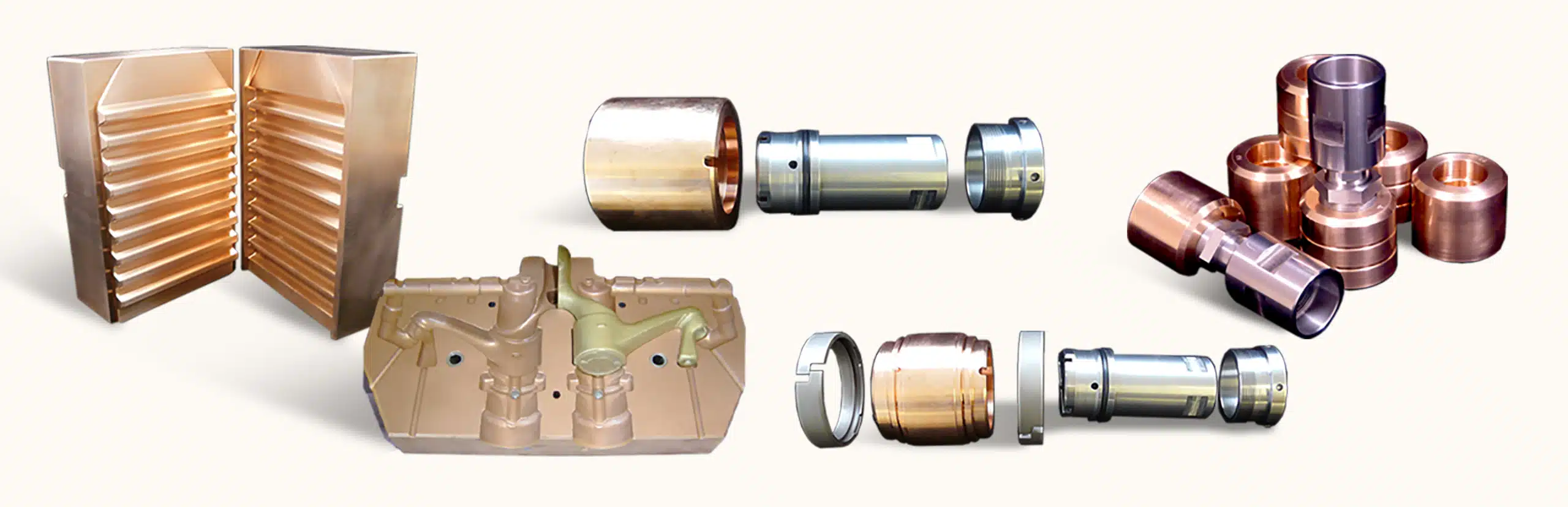

Casting Techonology

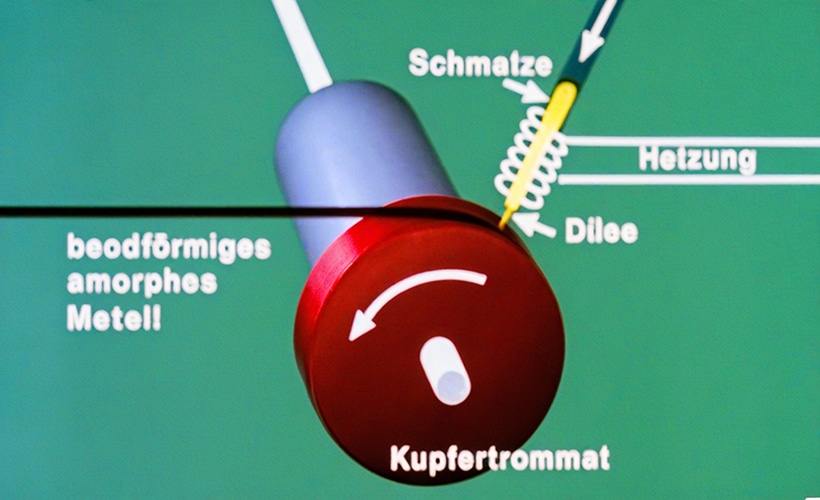

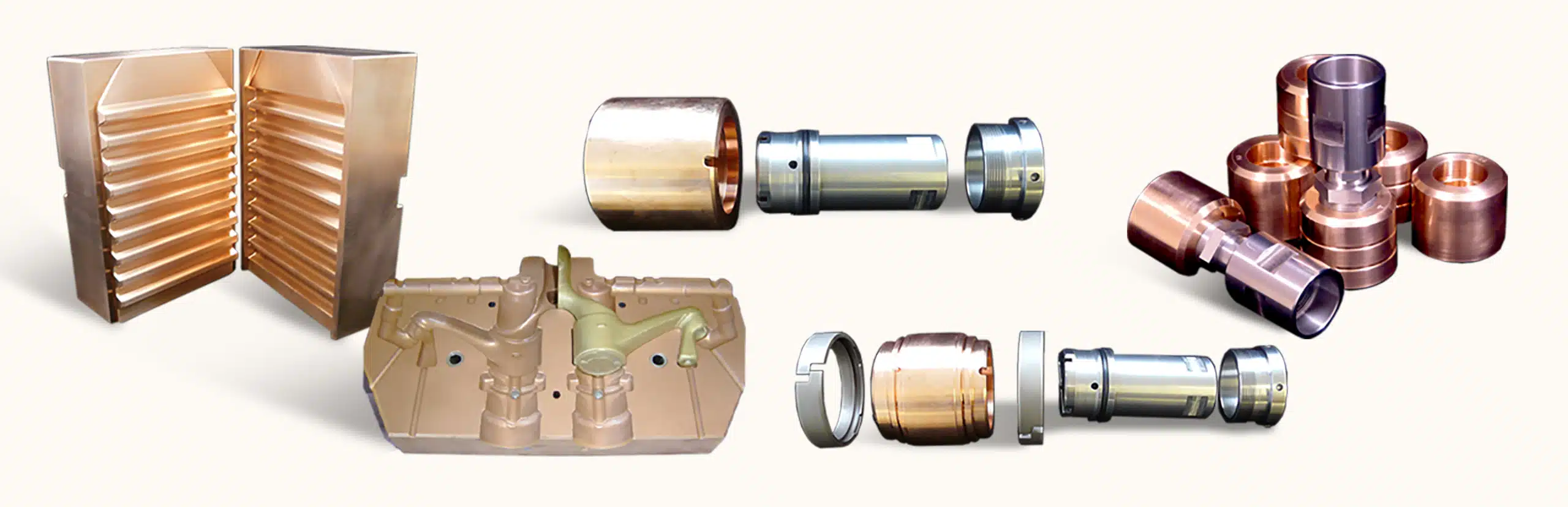

HOVADUR® special alloys showing excellent thermal conductivity are essential materials for construction in casting technology

Browse Casting Technology applications

About Casting Technology

Casting Technology

Your advantages:

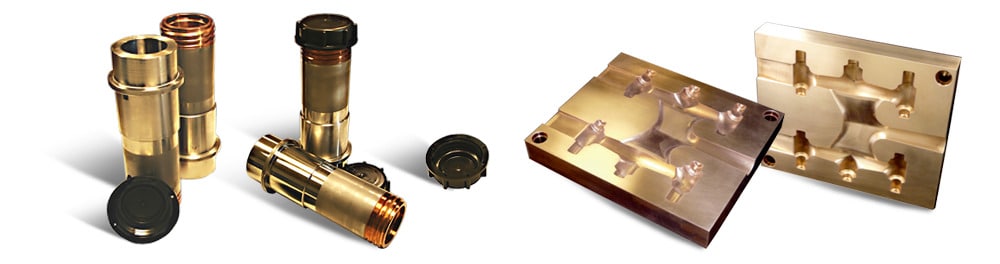

- Low piston wear

- Increased lifespan of the shot chamber

- Simple handling of the piston system

Our range of products:

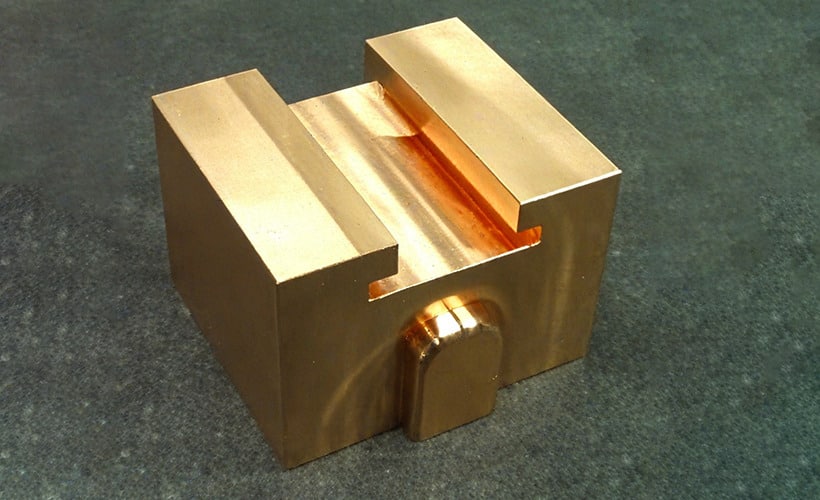

- Pistons > Piston Adapter Systems

- Shot chambers

- Die venting systems

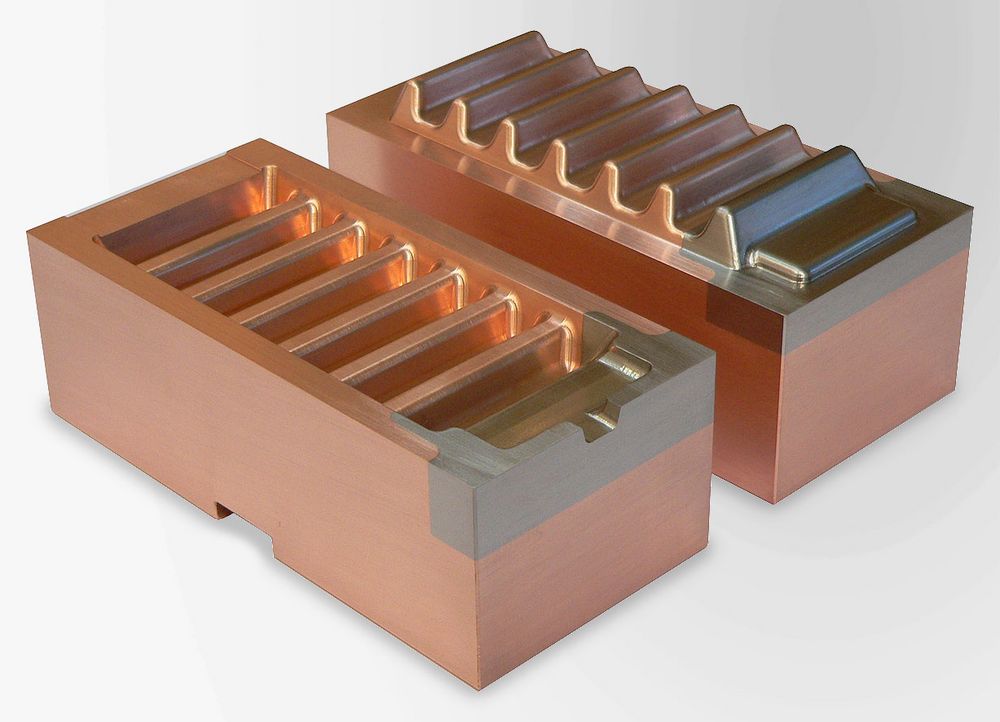

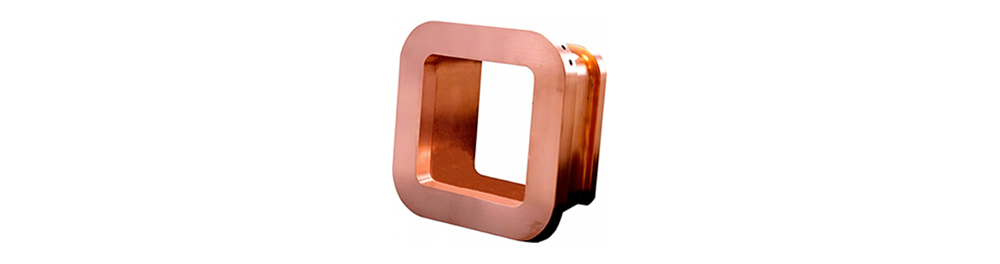

- Moulds for continuous casting